Release time:2025-03-24

Block Silicone: The Core Softening Agent for Next-Gen Textile Finishing

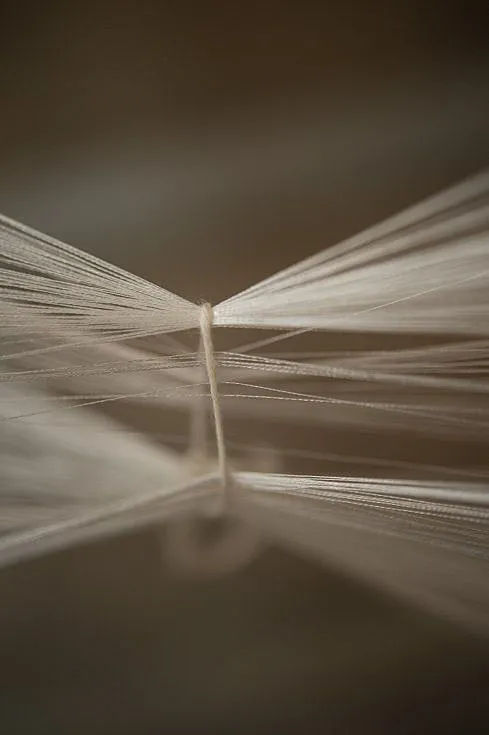

Block Silicone is a modified organosilicon material featuring a "hydrophilic-hydrophobic" block copolymer structure. Compared to traditional amino silicones, its unique molecular arrangement delivers balanced performance in textiles, particularly in softness, durability, anti-yellowing, and process compatibility, making it the preferred

choice for high-end textile functional finishing.

Key Performance Advantages of Block Silicone

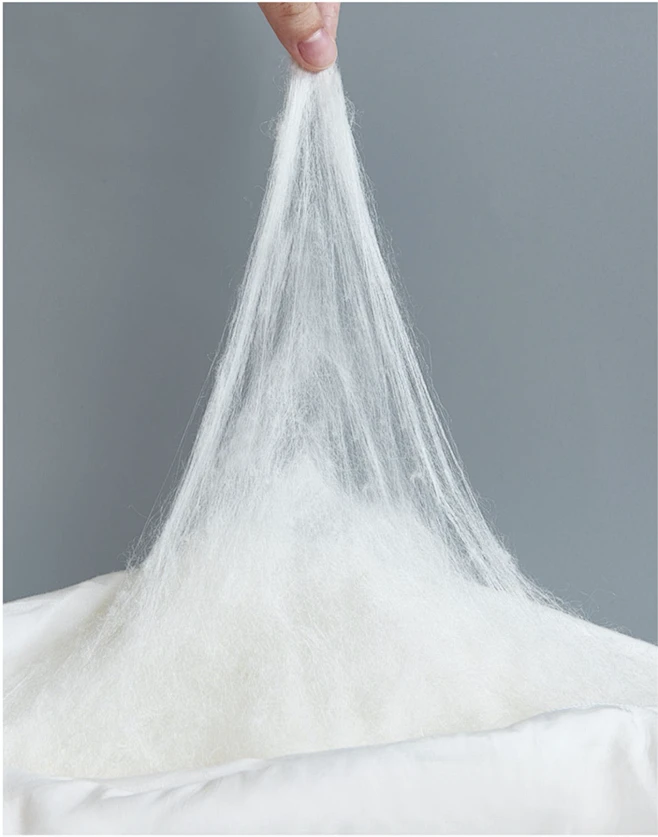

Ultra-Soft Hand Feel & Loftiness

The hydrophobic segments (e.g., polydimethylsiloxane) bond with fibers, while hydrophilic segments (e.g., polyether) extend outward, forming a "silky outer layer." This structure imparts silk-like smoothness and cotton-like loftiness, ideal for skin-friendly textiles like underwear, towels, and baby clothing.

Long-Lasting Wash Resistance & Anti-Static Properties

The chemical crosslinking of block silicone enhances wash durability, retaining over 80% softness after 30 standard washes. Additionally, hydrophilic segments provide anti-static effects, reducing skin cling in dry environments.

Low Yellowing Risk & High Compatibility

Traditional amino silicones often yellow due to amino oxidation, but block silicone’s optimized structure minimizes yellowing during heat setting or storage. It is compatible with cotton, linen, polyester, nylon, and blends, and can be combined with functional agents like antimicrobials or water repellents.

Block silicone operates under neutral conditions (pH 6–7), reducing wastewater treatment costs. Its low volatility complies with EU REACH and OEKO-TEX® standards.

Typical Applications and Case Studies

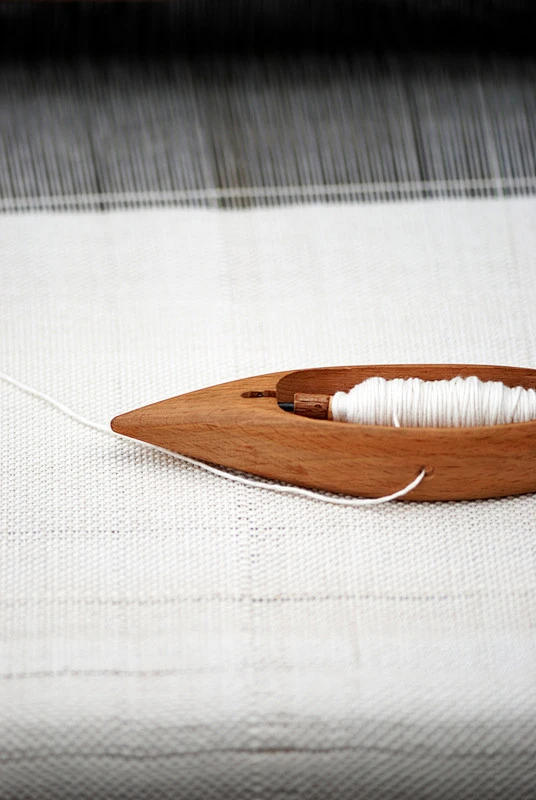

Luxury Soft Finishing for High-Thread-Count Cotton Shirts

A brand applied block silicone (3%–5% dosage) to 120-thread-count cotton shirts, achieving "cashmere-level" softness and 40% wrinkle resistance improvement, with a 25% increase in retail price.

Multi-Functional Finishing for Sportswear

Block silicone blended with moisture-wicking agents on polyester sportswear enhanced sweat evaporation by 35% while maintaining softness.

Sustainable Stone-Washing for Denim

Replacing pumice stones, block silicone combined with cellulase achieved a "green stone-wash" effect, cutting water use by 50% and eliminating pumice dust pollution.

Future Development Trends

Intelligent Customization: Tailored block silicones for specific fibers (e.g., super-hydrophobic or cooling variants).

Bio-Based Materials: Eco-friendly block silicones synthesized from renewable sources (e.g., palm oil derivatives).

Nano-Technology Integration: Nano-emulsification enhances permeability, enabling ultra-low dosage (0.5%–1%) applications.

Conclusion

Block silicone, with its molecular versatility and comprehensive performance, is redefining functional textile finishing. Choosing block silicone is not only an upgrade in quality but also a critical step toward sustainable manufacturing.

Contact Us

For customized block silicone solutions and technical specifications, visit our website or contact our technical team.

Here you can send us an inquiry concerning general questions

about abk.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.

I AcceptOur site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.

I Accept