I. Core Mechanisms of Stone Wash Enzyme SILIT®-2100+

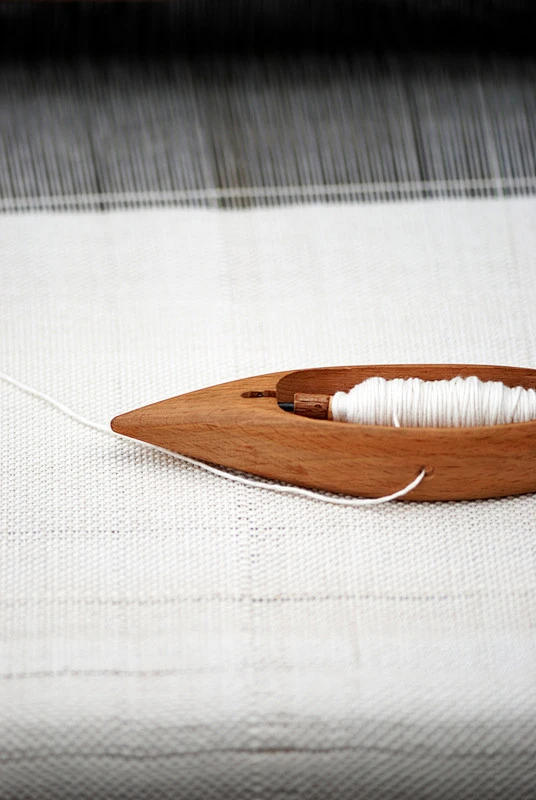

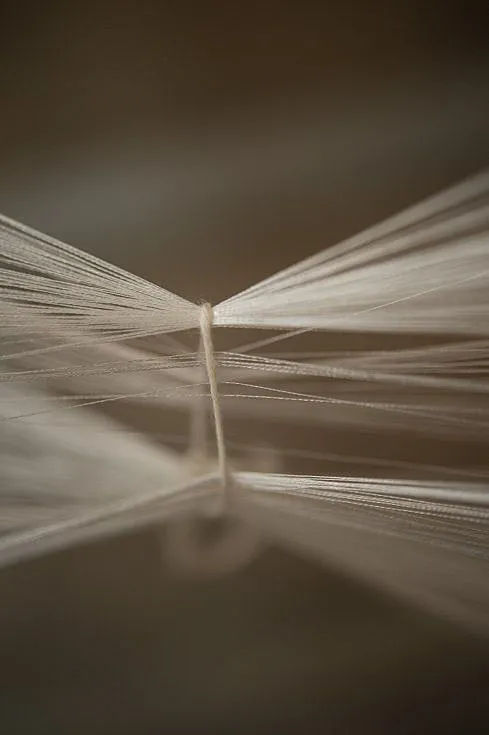

Stone Wash Enzyme SILIT®-2100+ (primarily cellulase-based composite biocatalysts) enable efficient color fading and texture enhancement by selectively degrading cellulose fibers on denim surfaces. Key principles include:

- Targeted Fiber Degradation: Under pH 4.5-5.5 and 45-55°C conditions, cellulase cleaves cellulose chains, disrupting indigo dye bonding for uniform fading13.

- Synergy with Physical Abrasion: Combined with pumice stones or artificial abrasives, enzymes accelerate localized dye removal, creating natural wear patterns and enhancing gray-white contrasts34.

- Low-Temperature Efficiency: Enzymatic reactions activate at lower temperatures, reducing energy consumption by 30% compared to chemical bleaching45.

II. Technical Advantages of Granular Enzymes

As a granular enzyme exporter, our products are optimized for industrial applications with distinct competitive edges:

| Feature | Traditional Liquid Enzymes | Granular Enzymes |

| Stability | Liquid form (requires cold chain) | Solid granules (stable ≤50°C)56 |

| Dissolution Speed | Slow activation (15-30 min) | Rapid release (≤3 min in water)57 |

| Eco-Friendliness | Contains preservatives (high COD) | Additive-free, 40% faster biodegradation24 |

| Versatility | Limited to denim washing | Compatible with denim, cotton, industrial filters5 |

III. Value Delivered to Global Clients

Cost Efficiency & Productivity

- 30-50% shorter processing cycles due to accelerated enzymatic reactions34.

- 50% reduced pumice consumption, lowering material costs and equipment wear35.

Sustainability Compliance

- 60% water savings with enzyme rinsing, aligned with EU REACH standards24.

- 120kg CO2 reduction per ton of denim processed (low-temperature operations)45.

Premium Quality Assurance

- Customizable effects (e.g., "frosted white" or "snowflake patterns") via enzyme concentration (0.5-1.5g/L) and reaction time adjustments36.

- Fabric protection: Surface-level fiber degradation minimizes seam damage14.

IV. Success Cases & Market Outlook

- Southeast Asian Denim Factories: Achieved 18% cost reduction and 25% faster delivery cycles by switching to granular enzymes, driving 40% annual export growth.

- European Eco-Brands: Developed zero-wastewater lines using granular enzymes + ozone bleaching, boosting product premium by 30%34.

Industry Insights:

- Global enzyme market to exceed 1.548 million tons by 2025, with 12% CAGR in detergent enzymes24.

- China’s granular enzyme exports grow 35% annually, driven by demand in the Middle East and Southeast Asia45.

V. Why Partner with Us?

- Custom Formulations: Protease/cellulase/amylase blends tailored to regional water quality57.

- End-to-End Support: Technical assistance from process optimization to wastewater management24.

- Cost Leadership: 15-20% price advantage over global competitors, backed by 10,000-ton production capacity (OEM supported).

Contact Us: Request free samples and the Denim Finishing Optimization Whitepaper to lead the sustainable manufacturing era!